Tunnel Engineering: Hidden World of Tunnels Beneath Our Feet

Table of Contents

Introduction: Beneath the bustling streets and landscapes we traverse lies a hidden world of tunnels that serve as the backbone of modern infrastructure. These marvels of engineering connect us, transport goods, and facilitate essential utilities, all while remaining largely unseen. Tunnel engineering, an intricate discipline, brings these subterranean passages to life, making them not only functional but also safe and efficient.

The Art of Tunnel Engineering: At its core, tunnel engineering is the art of carving passages through the Earth's crust. Yet, it's not as simple as digging a hole – it's a calculated endeavor that balances geological intricacies, structural integrity, and societal needs. While tunnels have existed throughout history, today's tunnel engineers draw from a deep well of scientific understanding and technological innovation.

Types of Tunnels and Their Uses: Tunnels serve multifaceted purposes, ranging from transporting people and goods to housing utilities that power our cities. They take various forms, each tailored to its purpose. Bored tunnels, for instance, involve digging through solid rock or soil using advanced machinery, while cut-and-cover tunnels are built by excavating a trench and covering it. Immersed tunnels, often used beneath bodies of water, are prefabricated sections submerged and aligned to create a seamless passage.

Challenges and Innovations: Tunnel engineering is rife with challenges. Engineers must navigate diverse soil conditions, address groundwater concerns, and account for potential geological shifts. Innovative solutions abound, such as tunnel boring machines (TBMs), which excavate while simultaneously installing tunnel linings. Ground improvement techniques, like grouting, stabilize soil, ensuring safer construction.

The Complex Construction Process: Tunnel construction is a meticulously planned process, involving various stages. It begins with thorough site investigation, understanding soil composition, and potential geological risks. Design follows, considering load-bearing capacities, traffic conditions, and emergency exits. Excavation commences, employing appropriate methods, and is accompanied by robust support systems – typically steel or concrete linings. The finishing touches include lighting, ventilation, and safety features.

Safety and Sustainability: Safety is paramount in tunnel engineering. Engineers adhere to rigorous safety protocols, accounting for both workers' well-being during construction and the safety of the eventual users. Emergency systems, like fire detection and evacuation plans, are integral. Sustainability is also a consideration, as energy-efficient lighting and ventilation systems minimize environmental impact.

Methods of Tunneling

1. Bored Tunneling: Bored tunneling, often conducted using Tunnel Boring Machines (TBMs), is a method employed to excavate through solid rock or soil. TBMs are colossal machines equipped with cutting heads that grind through the earth while simultaneously installing tunnel linings. This method is particularly efficient for longer tunnels and is a staple in projects like urban metro systems and highway expansions.

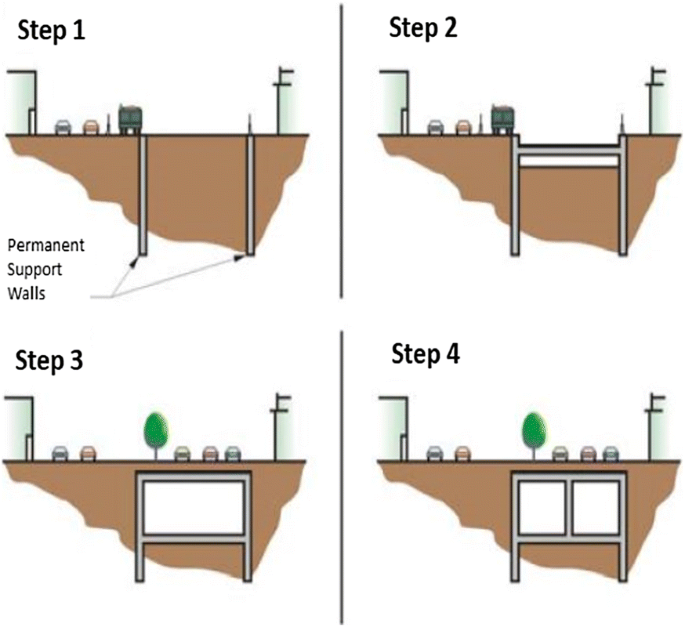

2. Cut-and-Cover Tunneling: Cut-and-cover tunneling involves excavating a trench, building the tunnel within it, and then covering it back up. This method is suitable for areas where the ground above the tunnel can be temporarily removed, like roadways or shallow bodies of water. While it's a cost-effective method, it can cause disruptions to existing infrastructure during construction.

3. Immersed Tunneling: When it comes to tunnels beneath bodies of water, immersed tunneling comes into play. This technique involves constructing pre-made tunnel sections on land, then floating or sinking them into place and aligning them to form a continuous passage. Immersed tunnels are commonly used for underwater transportation connections, like bridges and underwater highways.

4. Cut-and-Cover Immersed Tunneling: A hybrid method, cut-and-cover immersed tunneling combines the principles of both cut-and-cover and immersed tunneling. The tunnel is constructed in sections on land, immersed in water, and then covered with backfill to create a seamless passage. This method is often used for underwater roadways and rail connections.

5. Drill and Blast: Drill and blast tunneling is a traditional method that involves drilling holes into the rock face, placing explosives within the holes, and then blasting the rock to create a tunnel. While it may be slower and more labor-intensive than other methods, it's well-suited for rugged terrain and areas with varying geological conditions.

6. Sequential Excavation Method (SEM): Also known as the New Austrian Tunneling Method (NATM), SEM involves excavating small sections of the tunnel and then immediately reinforcing them with shotcrete and steel mesh. This method adapts to changing geological conditions more easily, making it suitable for tunnels through unstable rock formations.

7. Shield Tunneling: Shield tunneling utilizes specialized tunnel-boring shields that provide support as the tunnel is excavated. This method is particularly effective for creating tunnels in soft ground, preventing collapses while the tunnel lining is installed.

8. Sprayed Concrete Lining: In this method, known as "shotcrete," concrete is sprayed onto the excavated surface to form a durable tunnel lining. It's a flexible technique that can be adjusted based on the tunnel's condition and is often used in combination with other methods.

Suitability of Tunneling Methods

| Tunneling Method | Suitability |

|---|---|

| Bored Tunneling | Suitable for longer tunnels, especially in urban metro systems and highway expansions. |

| Cut-and-Cover Tunneling | Appropriate for areas where the ground above the tunnel can be temporarily removed, such as roadways or shallow water bodies. |

| Immersed Tunneling | Commonly used for creating underwater transportation connections, such as bridges and underwater highways. |

| Cut-and-Cover Immersed Tunneling | Ideal for underwater roadways and rail connections where the tunnel is constructed and then immersed. |

| Drill and Blast Tunneling | Well-suited for rugged terrains and areas with varying geological conditions. |

| Sequential Excavation Method (SEM) | Suitable for tunnels through unstable rock formations, where excavation and support installation are done in stages. |

| Shield Tunneling | Particularly effective for creating tunnels in soft ground, preventing collapses during lining installation. |

| Sprayed Concrete Lining | Flexible technique that can adapt to varying tunnel conditions and is often used in combination with other methods. |

Each tunneling method offers specific advantages and is chosen based on factors such as the geological nature of the site, project requirements, budget constraints, and safety considerations. As engineers continue to refine and innovate tunneling methods, the hidden world beneath us becomes not only a testament to human engineering prowess but also a vital network that fuels our modern lives. Whether you're driving through a tunnel or benefiting from utilities beneath the ground, remember the remarkable techniques that make it all possible.

Post a Comment